Magazine for the professional tire industry

Issue link: https://mtd.epubxp.com/i/762675

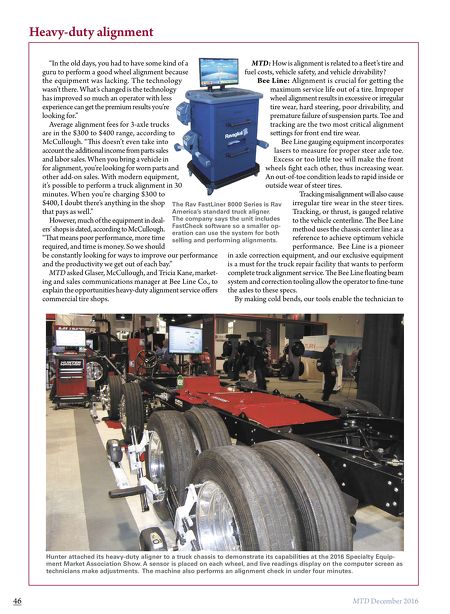

MTD December 2016 Heavy-duty alignment "In the old days, you had to have some kind of a guru to perform a good wheel alignment because the equipment was lacking. The technology wasn't there. What's changed is the technology has improved so much an operator with less experience can get the premium results you're looking for." Average alignment fees for 3-axle trucks are in the $300 to $400 range, according to McCullough. "is doesn't even take into account the additional income from parts sales and labor sales. When you bring a vehicle in for alignment, you're looking for worn parts and other add-on sales. With modern equipment, it's possible to perform a truck alignment in 30 minutes. W hen you're charging $300 to $400, I doubt there's anything in the shop that pays as well." However, much of the equipment in deal- ers' shops is dated, according to McCullough. "at means poor performance, more time required, and time is money. So we should be constantly looking for ways to improve our performance and the productivity we get out of each bay." MTD asked Glaser, McCullough, and Tricia Kane, market- ing and sales communications manager at Bee Line Co., to explain the opportunities heavy-duty alignment service offers commercial tire shops. MTD: How is alignment is related to a fleet's tire and fuel costs, vehicle safety, and vehicle drivability? Bee Line: Alignment is crucial for getting the maximum service life out of a tire. Improper wheel alignment results in excessive or irregular tire wear, hard steering, poor drivability, and premature failure of suspension parts. Toe and tracking are the two most critical alignment seings for front end tire wear. Bee Line gauging equipment incorporates lasers to measure for proper steer axle toe. Excess or too lile toe will make the front wheels fight each other, thus increasing wear. An out-of-toe condition leads to rapid inside or outside wear of steer tires. Tracking misalignment will also cause irregular tire wear in the steer tires. Tracking, or thrust, is gauged relative to the vehicle centerline. e Bee Line method uses the chassis center line as a reference to achieve optimum vehicle performance. Bee Line is a pioneer in axle correction equipment, and our exclusive equipment is a must for the truck repair facility that wants to perform complete truck alignment service. e Bee Line floating beam system and correction tooling allow the operator to fine-tune the axles to these specs. By making cold bends, our tools enable the technician to Hunter attached its heavy-duty aligner to a truck chassis to demonstrate its capabilities at the 2016 Specialty Equip- ment Market Association Show. A sensor is placed on each wheel, and live readings display on the computer screen as technicians make adjustments. The machine also performs an alignment check in under four minutes. The Rav FastLiner 8000 Series is Rav America's standard truck aligner. The company says the unit includes FastCheck software so a smaller op- eration can use the system for both selling and performing alignments. 46