Magazine for the professional tire industry

Issue link: https://mtd.epubxp.com/i/762675

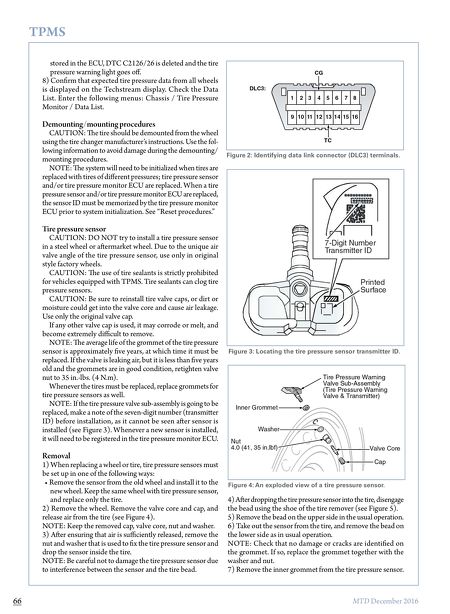

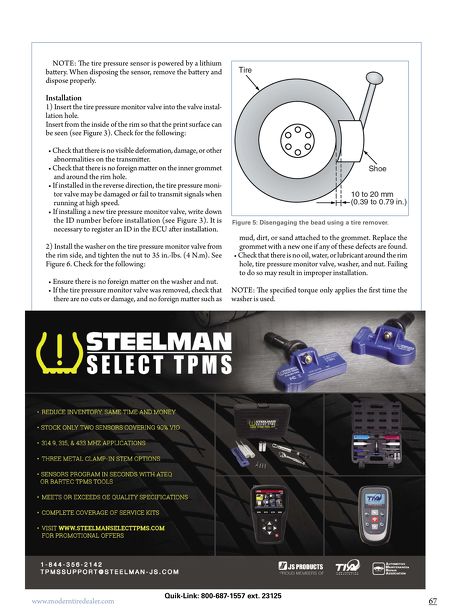

MTD December 2016 TPMS stored in the ECU, DTC C2126/26 is deleted and the tire pressure warning light goes off. 8) Confirm that expected tire pressure data from all wheels is displayed on the Techstream display. Check the Data List. Enter the following menus: Chassis / Tire Pressure Monitor / Data List. Demounting/mounting procedures CAUTION: e tire should be demounted from the wheel using the tire changer manufacturer's instructions. Use the fol- lowing information to avoid damage during the demounting/ mounting procedures. NOTE: e system will need to be initialized when tires are replaced with tires of different pressures; tire pressure sensor and/or tire pressure monitor ECU are replaced. When a tire pressure sensor and/or tire pressure monitor ECU are replaced, the sensor ID must be memorized by the tire pressure monitor ECU prior to system initialization. See "Reset procedures." Tire pressure sensor CAUTION: DO NOT try to install a tire pressure sensor in a steel wheel or aermarket wheel. Due to the unique air valve angle of the tire pressure sensor, use only in original style factory wheels. CAUTION: e use of tire sealants is strictly prohibited for vehicles equipped with TPMS. Tire sealants can clog tire pressure sensors. CAUTION: Be sure to reinstall tire valve caps, or dirt or moisture could get into the valve core and cause air leakage. Use only the original valve cap. If any other valve cap is used, it may corrode or melt, and become extremely difficult to remove. NOTE: e average life of the grommet of the tire pressure sensor is approximately five years, at which time it must be replaced. If the valve is leaking air, but it is less than five years old and the grommets are in good condition, retighten valve nut to 35 in.-lbs. (4 N.m). Whenever the tires must be replaced, replace grommets for tire pressure sensors as well. NOTE: If the tire pressure valve sub-assembly is going to be replaced, make a note of the seven-digit number (transmier ID) before installation, as it cannot be seen aer sensor is installed (see Figure 3). Whenever a new sensor is installed, it will need to be registered in the tire pressure monitor ECU. Removal 1) When replacing a wheel or tire, tire pressure sensors must be set up in one of the following ways: • Remove the sensor from the old wheel and install it to the new wheel. Keep the same wheel with tire pressure sensor, and replace only the tire. 2) Remove the wheel. Remove the valve core and cap, and release air from the tire (see Figure 4). NOTE: Keep the removed cap, valve core, nut and washer. 3) Aer ensuring that air is sufficiently released, remove the nut and washer that is used to fix the tire pressure sensor and drop the sensor inside the tire. NOTE: Be careful not to damage the tire pressure sensor due to interference between the sensor and the tire bead. 4) Aer dropping the tire pressure sensor into the tire, disengage the bead using the shoe of the tire remover (see Figure 5). 5) Remove the bead on the upper side in the usual operation. 6) Take out the sensor from the tire, and remove the bead on the lower side as in usual operation. NOTE: Check that no damage or cracks are identified on the grommet. If so, replace the grommet together with the washer and nut. 7) Remove the inner grommet from the tire pressure sensor. Figure 4: An exploded view of a tire pressure sensor. Figure 3: Locating the tire pressure sensor transmitter ID. Figure 2: Identifying data link connector (DLC3) terminals. 66